BMW N57 Engine Fitting Checklist | Essential Steps to Save Time and Money

Expert Guide & Pre-Installation Checklist for BMW N57 Engines

Replacing a BMW N57 engine is not just a repair; it’s a meticulous process that restores the heart of your vehicle. Installing this engineering marvel can prove to be overwhelming even for experienced mechanics. If you skip any critical precautionary step, it can lead to costly mistakes, unnecessary downtime or even the reinstallation of the engine. It’s not the result of lacking the skills but simply overlooking key details. We would love to help you avoid these pitfalls and have created a comprehensive pre installation guide for you. This step by step guide will ensure that your BMW N57 engine fitting process is smooth, efficient and trouble free.

Pre-Installation Checklist

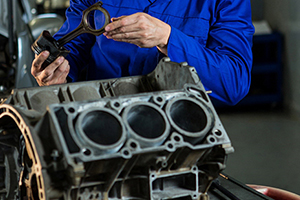

Identify the Cause of Engine Failure

Taking the time to thoroughly assess and prepare before installing your BMW N57 engine pays off immensely, ensuring a seamless and successful replacement. The first step is to identify the root cause of the previous engine failure. Bear in mind that it is not easy to pinpoint the exact cause but you can prevent the recurring problems by simply addressing the common issues such as coolant leaks or radiator malfunctions.

Cleaning and Preparing Components

Your next focus should be on cleaning and preparing the key components such as the oil filter and heat exchanger housing. Remove the debris from previous malfunctions and clean the dust and residue. While you are at it, replace the oil cooler gasket to ensure a secure seal and avoid leaks.

Sump and Oil Pan Adjustments

Sump and oil pan design require compatibility checks for the compatibility with your specific model. It is recommended that you swap the sump and pick up the pipe from the original engine. Those precautionary steps may seem time consuming and to some extent, budget draining as well but form the foundation for a successful installation.

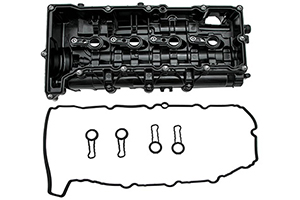

Injector Seals and Rocker Cover Gasket

To ensure the prevention of fuel and oil leaks, you must replace the injector seals and rocker cover gasket during engine installation which can save you from future trouble. Worn or damaged injector seals can contribute to inefficient combustion, power loss and carbon build up. Oil leaks are evident with a faulty rocker cover gasket compromising engine efficiency and cleanliness.

Priming the Engine Oil

A dry start can damage your engine so you must prime the engine with enough engine oil lubrication before you start it. To prime the oil, manually turn the engine by hand to circulate oil throughout the system. Make sure the oil has lubricated the camshafts and valve train. This process could save your engine from unnecessary strain during initial operations.

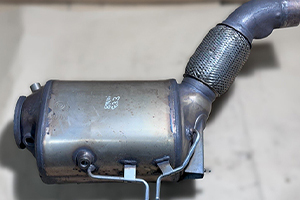

Cleaning the DPF

The most overlooked component during the engine replacement is usually the DPF or the Diesel Particulate Filter. It can restrict the airflow if it becomes clogged with soot or particulate matter. The result is reduced efficiency and triggered error codes. You can ensure better performance and engine longevity when you address the problems in the DPF in time and can save significant maintenance costs.

Detailed Component inspections and Final Preparations

Replacing and fitting a BMW N57 engine is an intricate and detailed task and seemingly minor issues can lead to significant problems down the line if left unaddressed. We have looked into the key components that require close attention and outlined final preparations to ensure a successful engine start.

Starter Motor

The starter motor is always hard to reach in the BMW N57 engines when fitted. So, the best practice is to always check the starter motor before installing the engine. The easiest way to do this is the place the starter motor on the ground and actuate it using a current to ensure it operates smoothly. Checking this vital component before the engine fitting can save you a significant amount of money and hassle.

Turbochargers

Turbochargers play a pivotal role in your engine’s performance, making their inspection a top priority. Start by checking the rear housing for any oil residue or wetness, which could indicate leaks. Next, inspect the impeller shaft for movement; there should be no in-and-out play and minimal side-to-side movement. For high-mileage vehicles, consider replacing both turbochargers, even if they appear functional, as wear and tear over time can lead to inefficiencies or failures. This proactive approach avoids costly engine removal later to access the turbos.

Intercooler

Previous engine failures can severely affect the intercooler as it often retains oil or water from previous engine failures. This can result in compromised performance of the new engine and reduced productivity. Removing the residue and cleaning the intercooler prevent the contamination of the engine and reduce the chances of engine damage. You should add this step to your must-do during the engine installation.

Flywheel and Clutch

For manual models, the flywheel and clutch should be inspected while the engine is out, as they are much harder to access once installed. Check the dual-mass flywheel for excessive movement or unusual noises when side-to-side moved. The clutch plate should have sufficient material and not be worn down to the rivets. If these components are nearing the end of their lifespan, replacing them now is a cost-effective and practical decision.

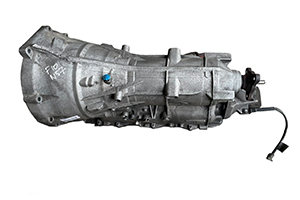

Automatic Gearbox

Engine replacement provides you an excellent opportunity to replace the gearbox if you are operating a vehicle with an automatic gearbox. Automatic gearboxes are often neglected over the vehicle’s lifetime and replacing them at the time of engine replacement can save you from the trouble from down the line. If not at least provide fresh oil and filters to improve the performance and longevity of the gearbox to ensure the smooth operation of the new engine.

Battery Check

A fully charged battery is essential for priming the diesel system and starting the engine. Before installation, test the battery to ensure it holds a charge and has adequate power. If the battery is in good condition, leave it on a trickle charge to maintain full power until it’s time to start the engine. This ensures a seamless start-up without risking damage to electrical components.

System Verification

As said before, engine replacement is an intricate task that requires multiple steps and involves several types of technicians to get it done perfectly. It helps to create a checklist for key tasks such as cleaning components, inspecting parts and priming the engine oil. Double-checking these steps minimizes errors, ensures a smooth installation, and enhances overall reliability.

Vehicles that use N57 Engines

| Model Name | Year | Engine | Picture |

|---|---|---|---|

| 330d | 2019 | N57 |  |

| 335d | 2019 | N57 |  |

| 430d | 2024 | N57 |  |

| 435d | 2024 | N57 |  |

| 530d | 2017 | N57 |  |

| 535d | 2017 | N57 |  |

| M550d | 2017 | N57 |  |

| X4 xDrive 20d | 2018 | N57 |  |

| X6 M50d xDrive | 2019 | N57 |  |

By carefully following these detailed inspections and final preparations, you can ensure your BMW N57 engine installation is not only successful but also smooth and free of unnecessary complications. Taking the time to address each component and step thoroughly lays the foundation for optimal engine performance, longevity, and peace of mind.

However, we understand that engine installations can be complex and time-consuming. That’s where [Website] comes in. With our expert team, specialized tools, and years of experience with BMW engines, we’re here to make the process hassle-free for you. Whether you need guidance, parts, or a complete professional installation, we have the expertise to get the job done right the first time.

Let us help you bring your BMW N57 engine back to life—efficiently, reliably, and without any of the headaches. Reach out today, and let’s get started!